Download Manufacturing Brochure

Download Manufacturing Brochure

Highlights for Manufacturing Software

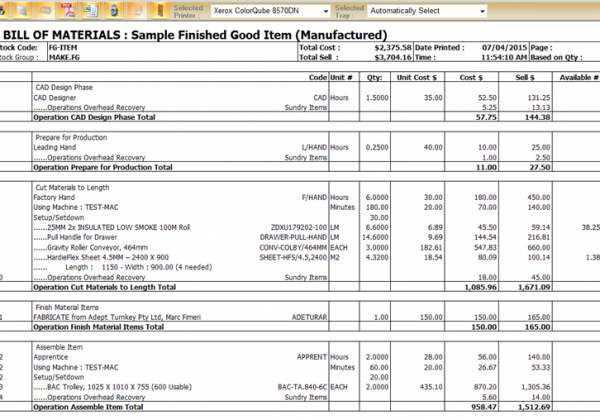

- InterAcct Manufacturing software combines a multi level Bill of Materials with a job costing Production system.

- Provide costing on finished goods (and sub assemblies). Allows you to combine Materials, Labour, Machines, Sub Contractors, Overhead Recovery, and Sundry costs.

- Considers for production cover of stock and/or sales order requirements.

- There are links to automatically create purchase orders, works orders, to reserve stock, and then to automatically issue materials to a production job.

- There is the option to input daily complete quantities and to automatically issue and calculate the related Cost Items used.

- The focus is on speed of data input, accuracy, and simplicity.

Why InterAcct Manufacturing Software?

|

Multi-Level - Sub Assemblies. BOM Software |

|

Labour and Machine Capacity Planning. |

|

Safety and Quality Control considerations. |

|

Link to drawings, specifications, and Photos. |

|

Automatic job accounting processes. |

|

Option of a simpler manufacturing software solution also for less cost. |

|

Factory Software for Scheduling and automated costings. |

Software benefits for Manufacturers

- These Sub-Assemblies speed up BOM setup as well as maintenance.

- Calculations of quantities required can be Each, Linear, Square, or Cubic – with wastage factors added.

- Graphic images can be attached to the BOM along with work instructions.

- BOM Duplication can assist with fast setup of Variants or similar items.

- Costs are updated any time based on the latest stock cost information.

- Materials can be issued to the job from stock automatically.

- Availability checks at any time to see if all materials are available to start production.

- Variance reports show the job’s budget and the actual cost items, so that you may adjust the BOM accordingly.

- Another version of the BOM software has been created for Paint & Chemical manufacture – with both volume and weight formulations in batch quantities with differing packaging sizes.

- There are numerous standard reports within InterAcct, and these can be changed to suit.

- The database of files, fields, and menus can also be changed to suit your requirements.

What has been made using InterAcct Manufacturing Software ?

- Light fittings

- Springs

- Windows Sashes

- Boat Trailers

- Parts of Railway systems

- Paint/ Chemicals/Ink Products

- Seating Solutions

- Standard fit out Cabinetry

- Machinery for Mining

- Kit Homes

- Animal Feed

- Telecommunication Trailers

InterAcct MRP Software/Production Management software links into a complete software application that tracks Accounting, Sales and Marketing, Inventory Control, Reorder Points and so much more.

There are multiple options with Manufacturing. To view these please see the video presentations or Contact our sales team to discuss your requirements.

You must be logged in to post a comment.